PARKING GARAGES

Using a PAM to perform concrete chipping in a rehabilitation project is a no-brainer. The PAM has been designed to address safety and production issues specifically targeting restoration contractor’s worst fear – concrete chipping.

BRIDGES & OVERPASSES

It's a well-known fact that as infrastructures are getting older, concrete delamination will occur.

The rehabilitation of this spalled concrete involves concrete chipping which is labor-intensive, strenuous and an inefficient task to perform.

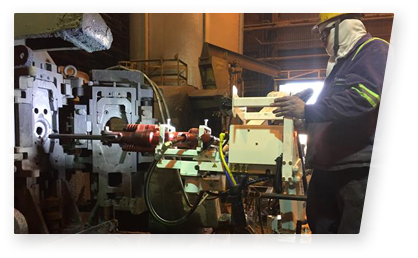

FOUNDRY

The arduous tasks of foundry maintenance can now be done with reduced risk of injury.

Applications such as chipping slag, refractory from ladles, auto-pour systems, furnace lips and refractory for relines can now be done safely.

TUNNELS, SUBWAYS & CULVERTS

As an infrastructure sub-category, tunnels, subways and culverts suffer from the same “structural cancer” such as concrete delamination as a result of corroded rebars.

MISCELLANEOUS APPLICATIONS

Beyond common structures, PAM has been used in many other applications facing the same ergonomic and productivity issues.

DRILLING

Beyond common structures, PAM has been used in many other applications facing the same ergonomic and productivity issues.

DEMOLITION

There are demolition projects that won’t allow the use of large scale demolition equipment. Some of these restrictions include access limitations, bearing capacity considerations, accuracy requirements and maximum levels of impact energy.

HYDRO DEMOLITION

Hydro demolition technique, as an alternative to the traditional chipping hammer, has been increasingly popular for the past 10 years. Mostly used for large surface preparation on concrete rehabilitation projects with robotic equipment, there are still smaller patches that cannot be done by robots and are completed by workers using handheld lances.