HYDRO DEMOLITION

Hydro demolition technique, as an alternative to the traditional chipping hammer, has been increasingly popular for the past 10 years. Mostly used for large surface preparation on concrete rehabilitation projects with robotic equipment, there are still smaller patches that cannot be done by robots and are completed by workers using handheld lances. Issues using handheld lances are not the same as working with hammers. There is much less vibration and airborne dust generated, however, the back thrust created by the flow and the pressure is a major concern as well as exposure to flying debris. The large amount of water used in this process along with the sludge adds to the back thrust concern since it creates a very slippery environment.

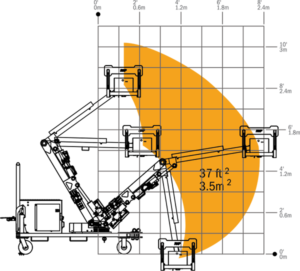

Additionally, since PAM takes all the loads, we are able to add a protective guard to keep flying debris away from the workers. Furthermore, you will be able to increase your flow and or the pressure since you are no longer limited to a back thrust a man can withstand, thus get an increase in productivity. PAM withstands a back thrust up to 1000 N (225 lbs).

The freedom of movement combined with the back thrust suppression enables you to blast concrete with the same ease as watering your garden.

***For safety purposes, the PAM needs to be slightly modified to interlock the controls with the unit.

RNP PAM HYDRO DEMOLITION

PLEASE CONTACT US TO DISCUSS YOUR SPECIFIC NEEDS & ISSUES.